Description

Our Jeep Wrangler JL/JT & JK steering stabilizer bracket addresses many common issues.

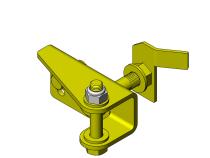

This is a simple bolt on 3/16s thick, gold zinc plated, double sheer bracket. It includes Grade 8 Hardware to properly clamp our new CNC laser cut and bent bracket to your factory axle mount.

This allows you to raise your factory or aftermarket stabilizer above your tie rod eliminating the possibility of hitting it on rocks or other obstacles.

One of the main key features with our JL/JK stabilizer bracket is that it doesn't block the track bar bolt head. Meaning you can check, and retorque your track bar Hardware without removing this bracket or your stabilizer.

It also comes with a new Grade 8 track bar bolt (TORUE SPEC 146 FT/LBS), with a flanged nut. So this makes it easier to install this new bolt, but also makes it less likely for it to loosen up for two reasons.

One, the flange can Not spin around without making contact with axle itself, and since the bolt normally has pressure on it, this makes it a lot less likely that it will loosen up.

Two, this is a top lock nut, which has the top thread section deformed to create two or three locking zones. This will easily start by hand, and then you will want to use a torque wrench and torque to 146 ft/lbs.

Notes

2007-2018 Jeep Wrangler JK will allow you to reuse your factory tie rod mount. Simply unbolt your steering stabilizer, bolt our new bracket on your axle, loosen and twist your stock tie rod mount above the tie rod, tighten and reinstall your stabilizer.

2018+ Jeep Wrangler JL & 2020+ Gladiator will require one hole to be drilled to mount this bracket. And will also require an additional tie rod mount. Part # COR-5209011 is the JL/JT packaged kit, which adds part # COR-5200940.

Please note these brackets are designed to be installed on factory axle bracket mounts, and also factory tie rods. Aftermarket tie rods will require proper mounting brackets.

Note: This kit uses a Top Lock - it will Not screw on by hand. Start by hand, then use torque wrench.

Uniquely shaped threads provide a vibration resistant friction fit, so the nut stays put. These all metal locknuts withstand higher temperatures than nylon insert locknuts.

Top thread section is deformed to create two or three locking zones; they start easily by hand, then must be wrenched into final position.

Grade C equivalent to Grade 8. IFI-100/107 Grade C. ANSI B1.1 UNC or UNF Class 2B thread requirement. Zinc plating, retards the corrosion rate in a normal atmosphere.